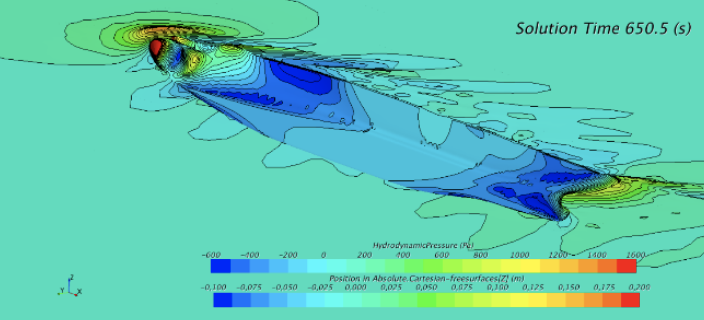

Having noticed the advantages of the suction effect created in way of the middle/trailing area of bulbous bow, Interprogetti Genova has carried out theoretical and experimental investigations with a model of a tanker aimed to replace the bulbous bow with adjustable fins fitted at bow and capable of creating variable lifting effects..

Although the results a number of tests encouraged to continue (EF = 0.98÷1.04) slightly higher than 1), for practical reasons (risk of damage caused by floating objects and anchor chains, structural issues, mechanical complications etc.) it was decided to abandon the venture.

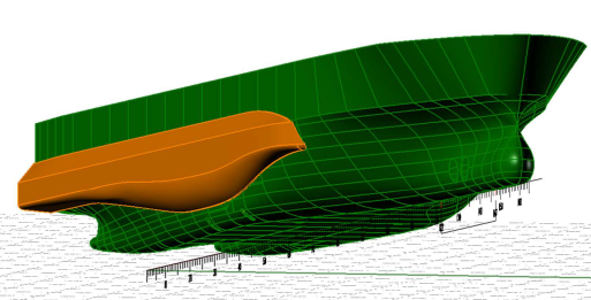

Other interesting results which, however, did not lead to practical applications on ships as they were not considered sufficiently worth by our customers (EF = 0.99÷1.04) where obtained applying appropriate shaped pads on the sides of the bulb as shown in the photo below.

Interprogetti Genova has been always dealing with research works with the aim of conceiving products of interest for the reference markets and taking care to characterize the conceived devices with “effectiveness factor” (“EF”) higher than 1 as much a s possible. Click here and discover more research and development work.