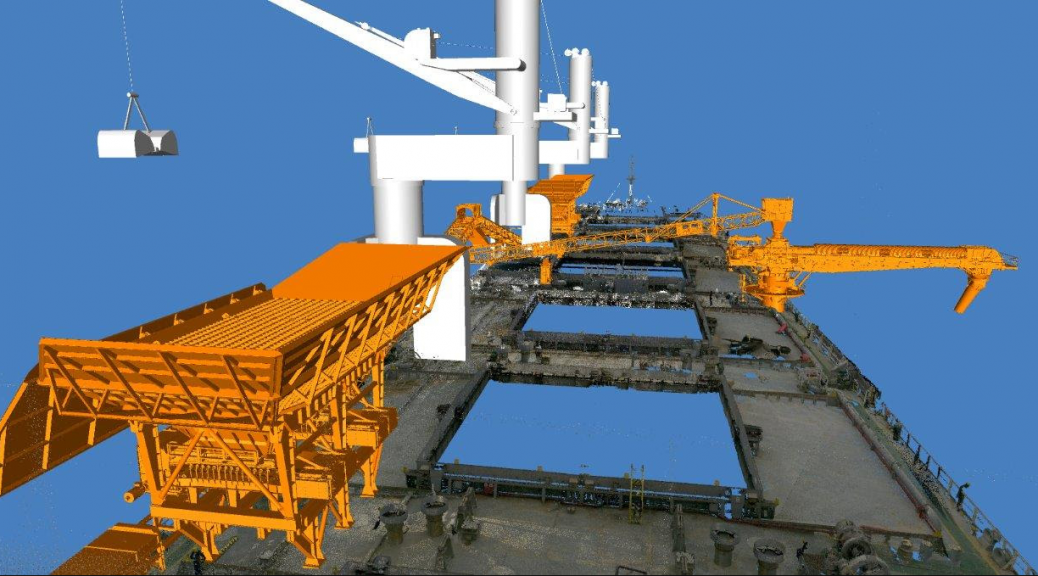

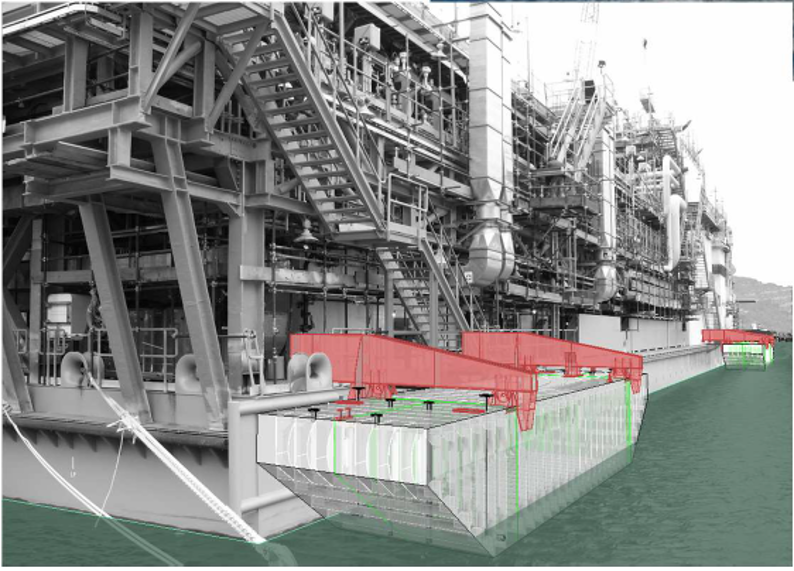

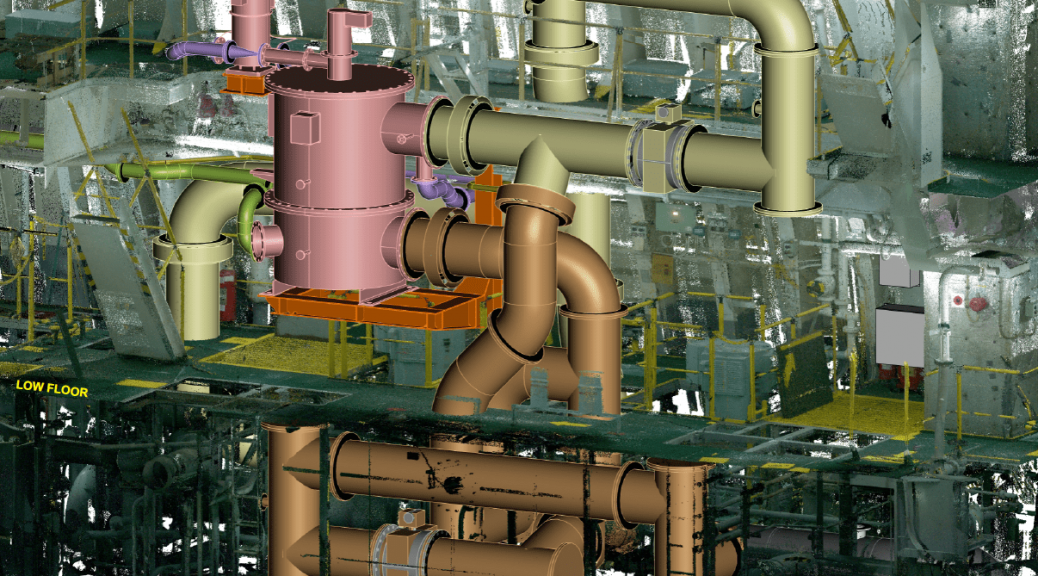

The job consisted in designing suitable modules sized and fitted as an ISO 40 TEU container to form a trimaran for shallow water trenching operation. The modules are connected each other through special bolted connections and transversal beams capable of withstanding any kind of environmental loads from any direction allowing therefore unrestricted service to the unit.

The advantage of such a design consists in avoiding expensive overseas towing operations to transfer the unit from one offshore site to another. As a matter of fact, after having completed trenching operation in one site, the trimaran can be simply disassembled in different 40 TEU containers. Transfer to a new oversea offshore site is simply realized by transporting the different modules by truck and then by loading the same onboard of a standard containership, allowing to minimize actual transport expenses.

Interprogetti Genova has been dealing with the design of new builds and conversions of a wide range of ships such as self-discharging bulk carriers, floating transhipment terminals, livestock carriers, tugs, oil & chemical tankers, ro-ro cargo, ro-ro pax, passenger ships, yachts, barges, offshore units, etc. Click here and discover more design and engineering work.